|

|

|

|

Products

》》hydraulic

lathe |

|

| | |

|

Video Show

Video Show

|

|

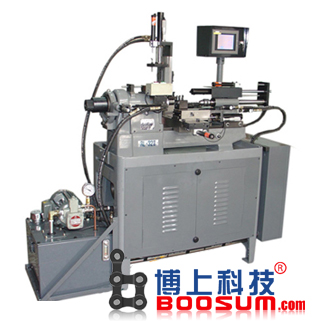

Automatic feeding

machining hydraulic

automatic lathes

(automatic

hydraulic milling machine)

adopts mechatronics

design, small size,

compact structure,

suitable for all types

of

automatic

small parts

machining,

according to the

complexity of the workpiece, the

simple choice of

hydraulic automatic

lathe

parts

, the use of

PLC +

hydraulic system

control,

general

assembly of the

vibration plate,

hopper

automatic feed mechanism

to achieve

automatic

workpiece

machining.

Automatic feeding

hydraulic automatic

lathes

machining

processing efficiency,

a

person may see

more than one,

labor intensity

is small,

built

more than a dozen

different sets of

procedures,

product

manufacturing processes

to meet the general

requirements

(such as car

cylindrical,

flat face, drill

hole, tapping,

cutting, etc.)

Automatic feeding

hydraulic automatic

lathes

machining

general technical

parameters are as follows:

Range

suitable for processing

shapes: round,

square, hexagonal

Workpiece length

:5-130mm (can

be customized)

Workpiece

diameter:

Φ3-30mm (can be increased)

Processing speed

:8-15

/ min

Processing range:

step

class

Motor power:

1.5/2.2KW

Spindle speed:

2800r/min (optional

frequency control)

Power supply voltage:

380v 50hz

Machine weight:

about 550 kg

Feeding method:

forward or

backward

feed

material

(material

suitable for

advancing

material

generally

short

and long

material

suitable for

backward material,

but not

absolute, according

to the workpiece

will vary) |

|

| | | | |