|

|

|

|

Products

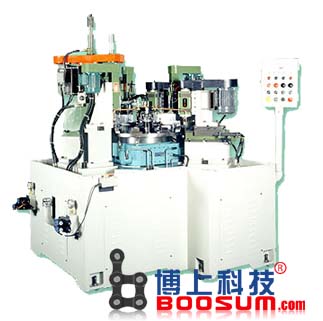

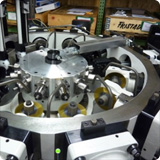

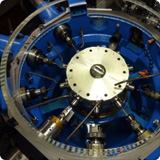

》》Rotary table machine--rotary transfer machine |

|

| | |

|

|

|

|

rotary transfer machine : |

|

Features:A rotary transfer

machine is a machine tool, typically for metal

working by machining, comprising a large

indexing table with machining stations

surrounding the table. Such rotary transfer

machines are used for producing a large lot of

parts in fairly short cycle times.In

rotary transfer machines, the workpieces are

located and clamped in pallet type fixtures that

are indexed in a circular path. During one

cycle, sequential machining operations are

performed simultaneously on the workpieces. The

indexed table turns vertically or horizontally,

and its movement could be continuous or

intermittent. As the indexing table turns, the

subsequent machining operation is repeated on

the workpiece which was just machined by the

previous station. This design combines automated

part feed with simultaneous operations, enabling

rapid completion of parts. |

|

|

|

Automatic

rotary transfer machine

set plus

machine tools,

processing

machines

replace

paddlewheel

best equipment,

high-quality, high-precision,

high-efficiency

processing of various

metals copper and

aluminum parts and

machinery-related

parts.

Mechanical processing

such as: turning,

milling surface,

milling,

drilling, tapping,

molding.

Multi-directional

processing, product

complete

one cut, do not do

secondary processing.

Processing materials

such as;

iron, aluminum,

copper, stainless steel,

optional automatic loading and

unloading system.

High affinity

disc

interface, beginners

are easy to operate.

The

workstation can be

equipped with different

functions, such as: car

sales, drilling,

milling, face milling

to do

the project design. |

|

Model |

ZHBS-GS-006-1 |

ZHBS-GS-006-2 |

ZHBS-GS-006-3 |

|

Hydraulic

motors |

4P 4KW |

4P 5.5KW |

4P 5.5KW |

|

Drilling

motor |

4P 1.5KW |

4P 2.2KW |

4P 4KW |

|

Tapping

motor |

4P 1.5KW |

4P 2.2KW |

4P 4KW |

|

Max diameter |

20MM |

30MM |

60MM |

|

Maximum machining

length |

100MM |

100MM |

100MM |

|

The average

processing speed |

8 seconds |

10 seconds |

10 seconds |

|

Processing materials |

iron, copper,

aluminum, stainless

steel |

|

Machine size |

2100×1900×2150 |

2100×1900×2250 |

2300×1900×2250 |

|

|

| | | | |