The dual head servo automatic tapping machine is an efficient, precise, and flexible special purpose machine automation processing equipment, widely used in the tapping processing technology of various metal materials.

The non-standard double head servo automatic tapping machine is an automated equipment with special design and functions, mainly used to machine precise threads on workpieces. Here is a brief introduction to it:

Design features:

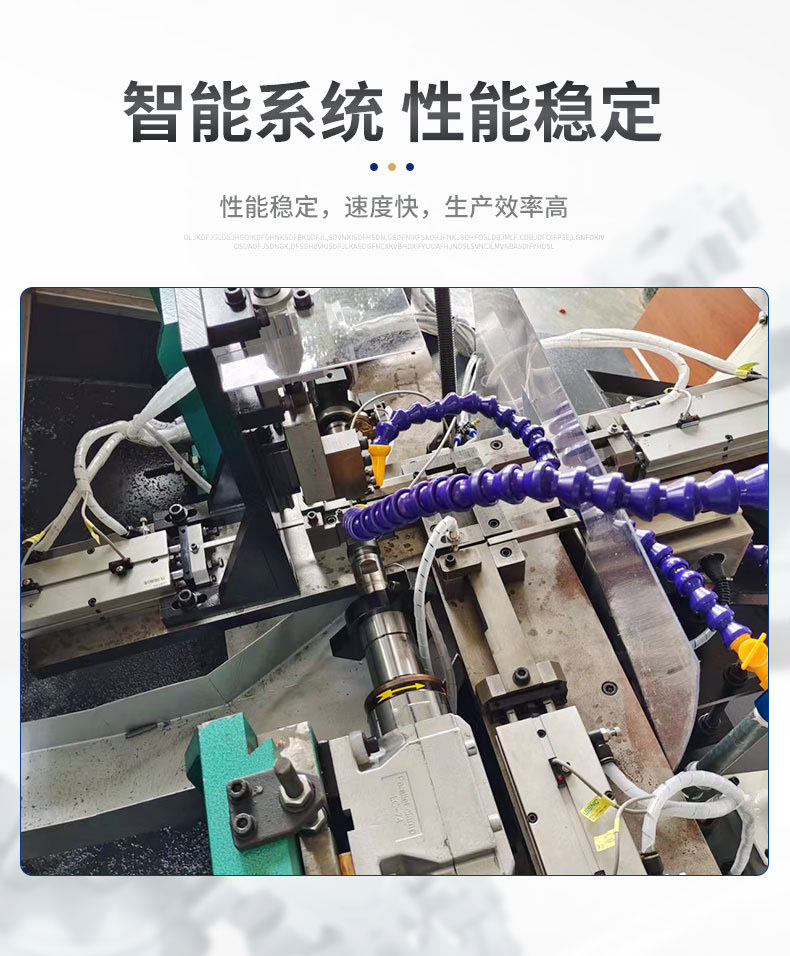

Double head design: The equipment is equipped with two independent tapping heads, which can simultaneously or independently tap the workpiece, greatly improving production efficiency.

Highly automated: Through advanced servo control systems and sensors, servo automation operations such as feed, positioning, clamping, tapping, and unloading are achieved, reducing manual intervention and improving production efficiency and processing quality.

High precision: The equipment adopts a high-precision transmission system and control system to ensure the stability and accuracy of the tapping process, meeting the requirements of high-precision machining.

Flexibility: Non standard design allows equipment to be customized according to different workpieces and processing requirements, meeting various special processing requirements.

working principle:

The workpiece is clamped on the workbench of the equipment to ensure stability and fixation.

Before tapping, cutting fluid can be applied to the workpiece as needed for cooling, lubrication, and cleaning.

The electronic control system controls parameters such as stroke, position, and speed to ensure that the cutting tool performs tapping operations in the optimal state.

The motor drives two tapping heads to rotate, and the servo starts the tapping operation. During the tapping process, the tool cuts through the metal and retracts to its initial position after completion.

Application areas:

Non standard dual head servo automatic tapping machines are widely used in the mechanical manufacturing and processing industry, especially in fields that require high-precision and high-efficiency thread processing.

For example, threading of body, frame, chassis, engine and other components in industries such as automobiles, motorcycles, aerospace, and precision electronic parts manufacturing.

Advantages:

Improve production efficiency: The dual head design allows the equipment to simultaneously perform tapping operations on two workpieces, greatly reducing processing time.

Reduce labor intensity: Highly automated operations reduce manual intervention and labor intensity.

Improving machining quality: High precision transmission and control systems ensure the stability and accuracy of the tapping process.

High flexibility: The non-standard design allows the equipment to be customized according to different workpieces and processing requirements.

The non-standard dual head servo automatic tapping machine is an efficient, high-precision, and highly automated thread processing equipment, suitable for high-precision thread processing needs in various mechanical manufacturing and processing industries.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen