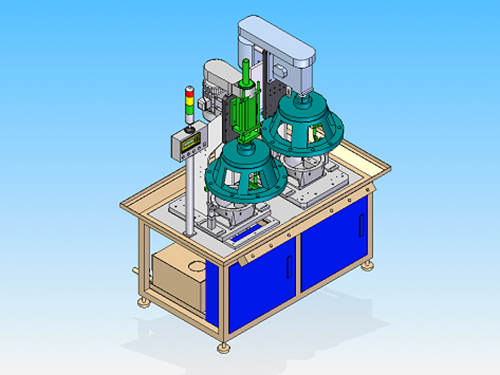

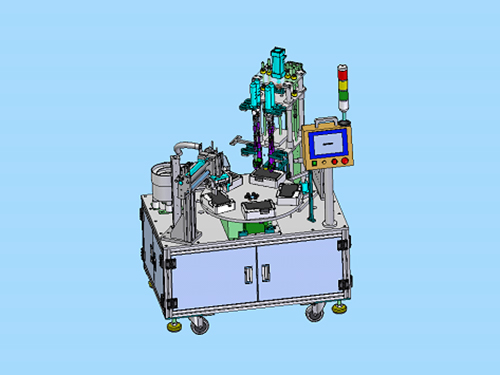

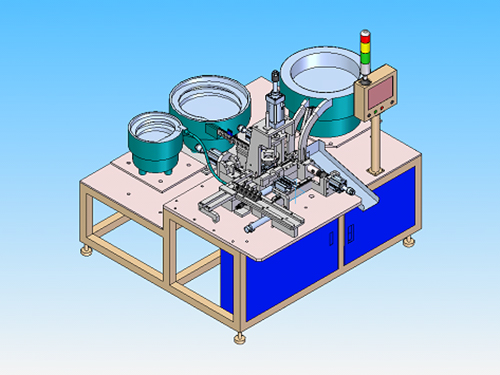

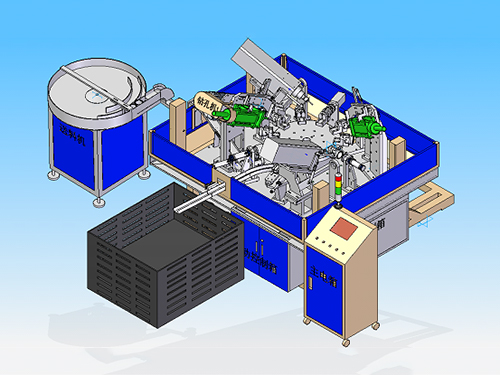

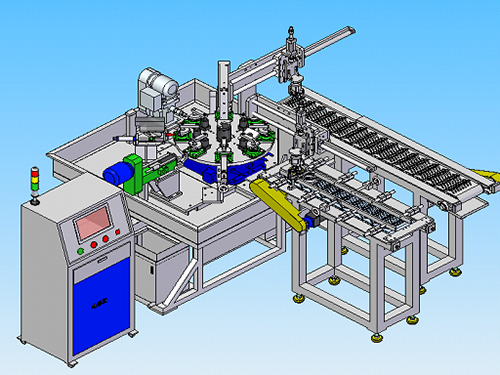

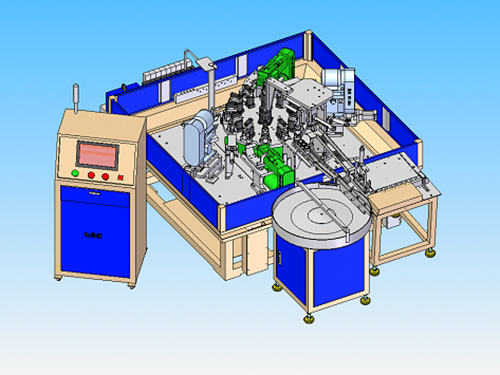

A multi position rotary table processing machine is an efficient and multifunctional processing equipment, with its core component being a rotary table with a circular or ring-shaped structure. The turntable can rotate and stay in different positions, with each position corresponding to a workstation where workpieces can be processed, assembled, inspected, and other operations.

The working principle of a multi position rotary table processing machine is that when the

rotary table rotates to a certain workstation, the positioning device positions the workpiece

on that workstation and then performs the corresponding processing or operation. After the

processing or operation is completed, the turntable continues to rotate to the next workstation,

repeating the above process until all workstations have completed the processing or operation.

This design allows workpieces to be continuously processed or inspected between multiple

workstations, greatly improving production efficiency.

The multi position rotary table machining machine has a high degree of flexibility in structure,

and can be configured with multiple working positions according to different machining needs,

achieving continuous operation of multiple machining processes. For example, while drilling at

one workstation, another workstation can perform tapping operations, greatly reducing the

downtime in the production process and increasing production capacity. In addition, the

speed of the turntable can be infinitely adjusted, and the smoothness of starting and stopping

is extremely high, making the machining process more stable and reliable.

Multi power rotary table processing machines are widely used in various manufacturing fields,

such as automotive parts, photovoltaic 5G, hardware processing parts, electronic components,

plastic products, electrical and bathroom appliances, etc. Its efficient, precise, and multifunctional

characteristics enable enterprises to better meet market demand, improve production efficiency,

reduce production costs, and thereby enhance market competitiveness.

Overall, multi position rotary table machining machines play an increasingly important role in

manufacturing due to their high efficiency, flexibility, and versatility, becoming an important tool

for enterprises to improve production efficiency and promote industrial upgrading.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen