The special-shaped copper strip forming machine usually provides customized services due to the different requirements of copper strip shape and performance in different industries. Users can choose the appropriate machine model and configuration according to their own needs to meet specific production requirements

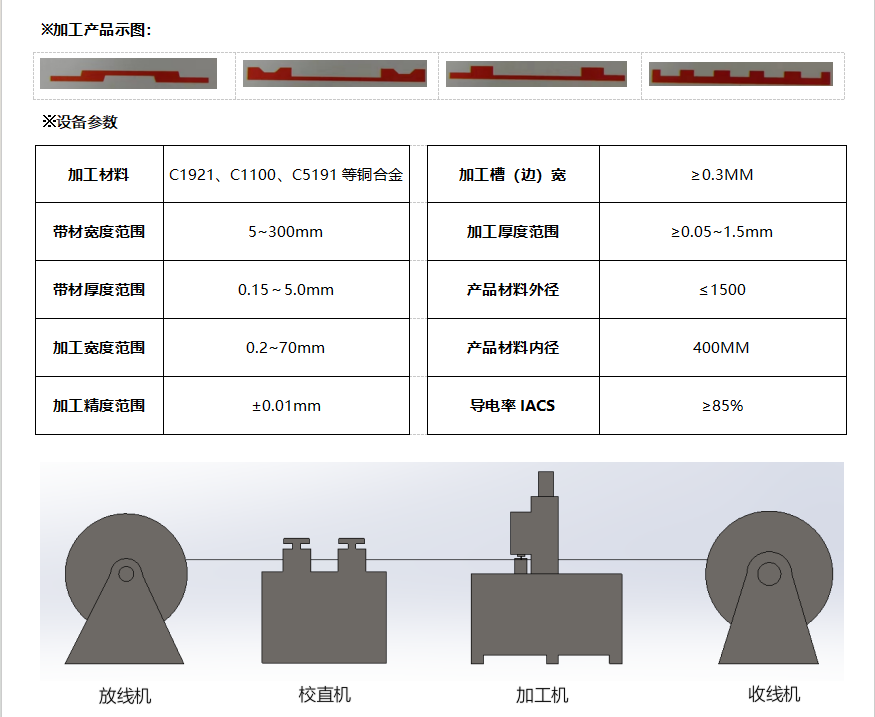

A special-shaped copper strip processing machine is a mechanical equipment specifically designed for manufacturing copper strips with non-standard shapes or special cross-sections. This machine can perform precise milling and other processing on copper strips according to production needs, thereby producing special-shaped copper strips that meet specific requirements.

Main features:

High precision machining: The special-shaped copper strip machining machine is usually equipped with a high-precision control system and tool system, which can ensure the accuracy and consistency of the copper strip during the machining process.

Strong flexibility: Due to the diversity of copper strip shapes, special-shaped copper strip processing machines need to have a high degree of flexibility to adapt to the production needs of copper strips of different shapes and specifications.

High efficiency: In order to improve production efficiency, special-shaped copper strip processing machines usually adopt automated and intelligent control systems, which can continuously and stably perform processing operations.

Safe and reliable: The machine design considers the safety of operators and is equipped with corresponding safety protection devices to ensure the safety of personnel and equipment during the processing.

Application areas:

The special-shaped copper strip processing machine is widely used in electrical, electronic, communication, construction, automotive, aviation and other fields to produce various copper strip products with special shapes and properties, such as connectors, heat sinks, conductive strips, etc.

Customized services:

Due to the different requirements for the shape and performance of copper strips in different industries, special-shaped copper strip processing machines usually provide customized services. Users can choose the appropriate machine model and configuration according to their own needs to meet specific production requirements.

Brand and Price:

There are multiple brands and suppliers in the market that produce special-shaped copper strip processing machines, and prices and performance vary depending on factors such as brand, model, and configuration. When choosing, users should comprehensively consider factors such as price, performance, and after-sales service to choose the most suitable product for themselves.

After-sale service:

When purchasing a special-shaped copper strip processing machine, suppliers usually provide comprehensive after-sales service, including equipment installation, debugging, training, maintenance, etc. These services can ensure that users receive timely technical support and assistance during use, solve problems that arise, and ensure the normal operation of equipment.

The special-shaped strip processing machine is a production equipment specifically designed for processing special-shaped copper and aluminum strips. It can efficiently and accurately process strips of various shapes, sizes, and materials, thus meeting the diverse needs of irregular strips in industrial production. The special-shaped strip processing machine has broad application prospects in manufacturing, aerospace, automotive, electronics and other fields.

From the perspective of working principle, the special-shaped strip processing machine achieves precise control and efficient processing of the strip through advanced mechanical, electrical, and control systems. It adopts high-speed forming and milling technology, which can complete a large number of processing tasks for irregular strip materials in a short period of time. At the same time, the special-shaped strip processing machine also has the characteristics of high automation and intelligence, which can automatically adjust processing parameters to ensure processing quality and efficiency.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen