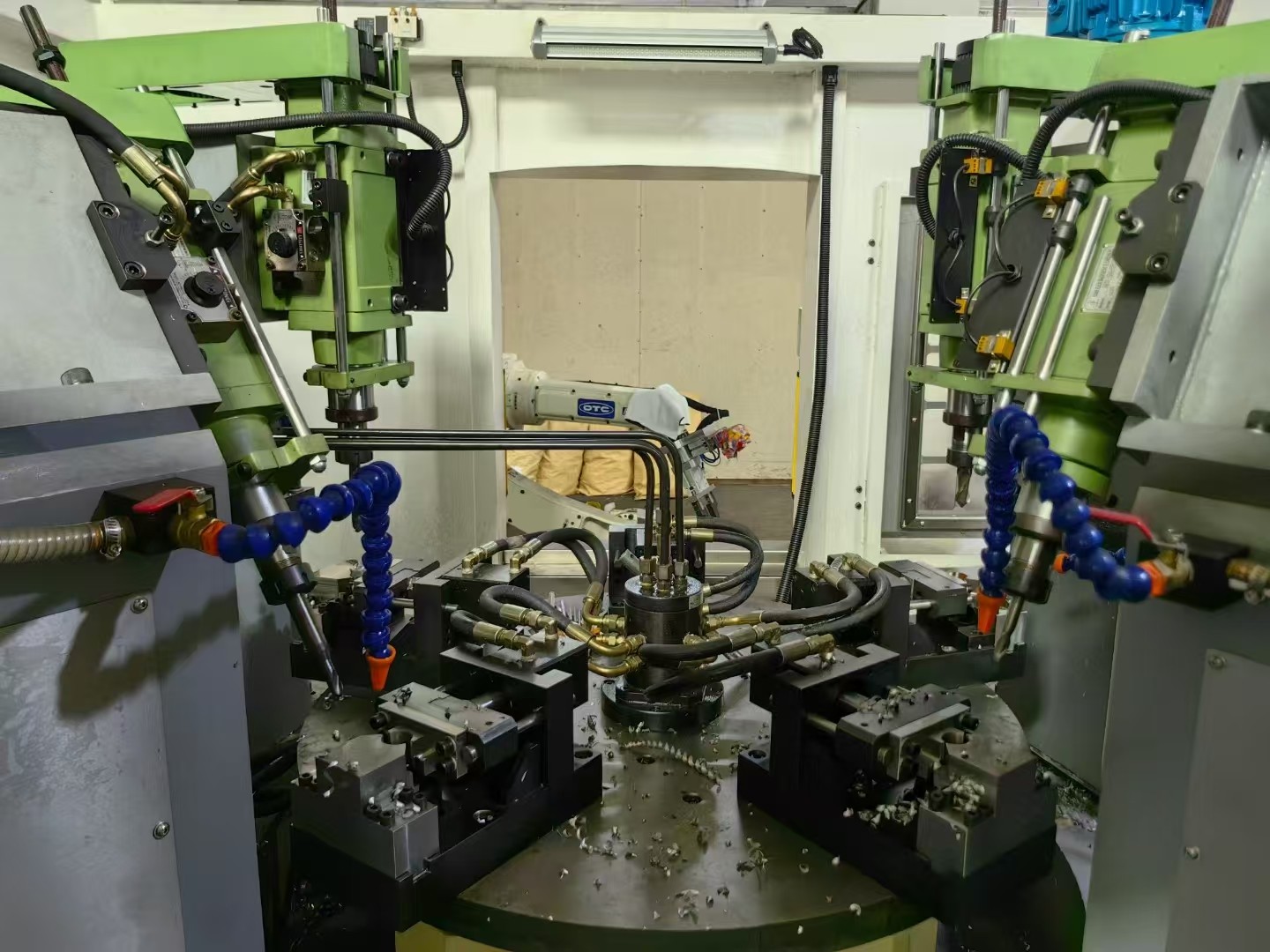

The rotary multi position machining machine has many advantages. Firstly, its multi station design allows each station to work independently, forming multiple processing steps, greatly reducing the ineffective time in the production process and improving production capacity. Secondly, the rotary design allows for unidirectional flow of materials, which is beneficial for the arrangement of site processes. Furthermore, the speed of the turntable can be infinitely adjusted, and the smoothness of starting and stopping is extremely high, ensuring the stability and accuracy of the machining process.

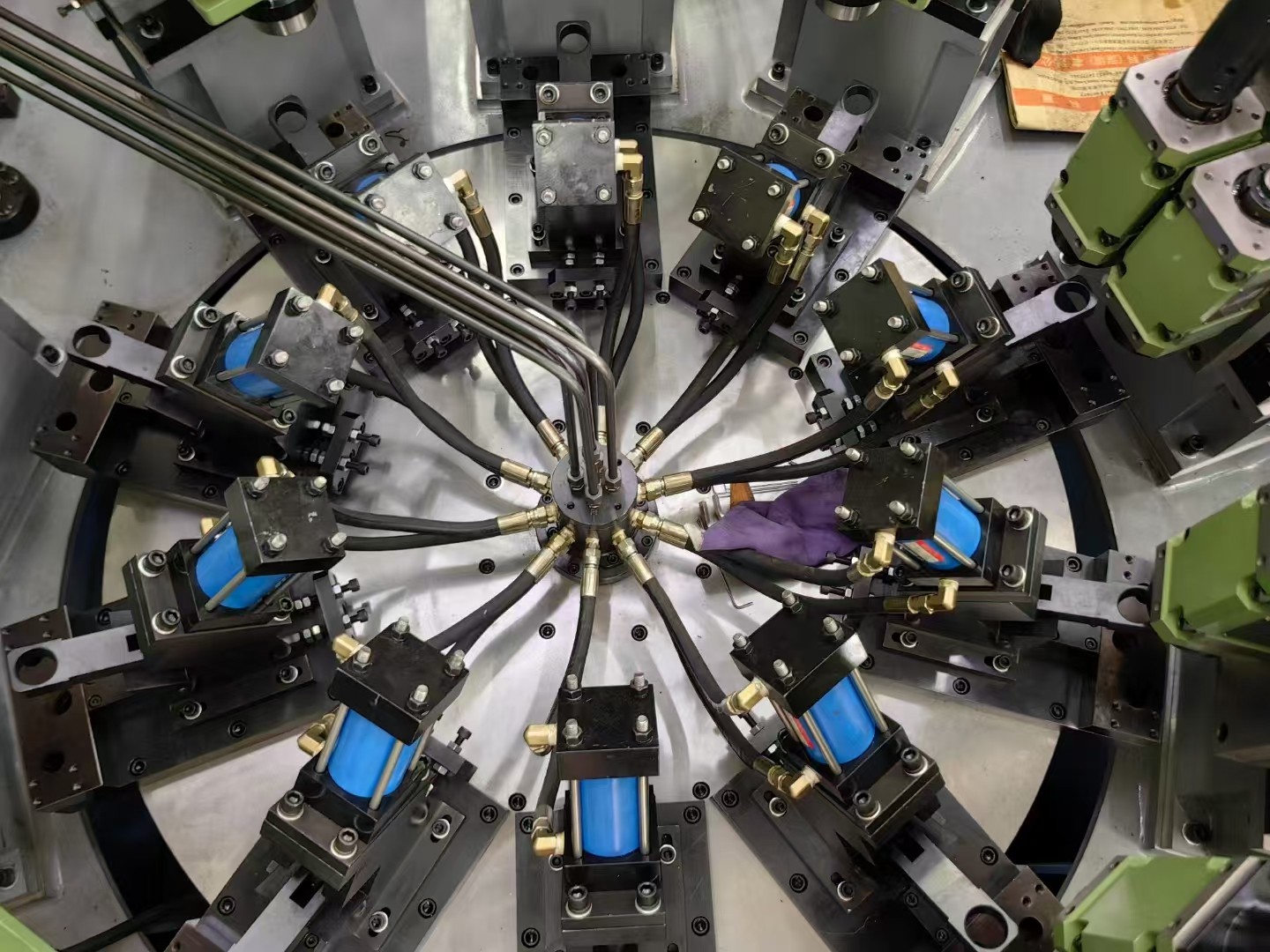

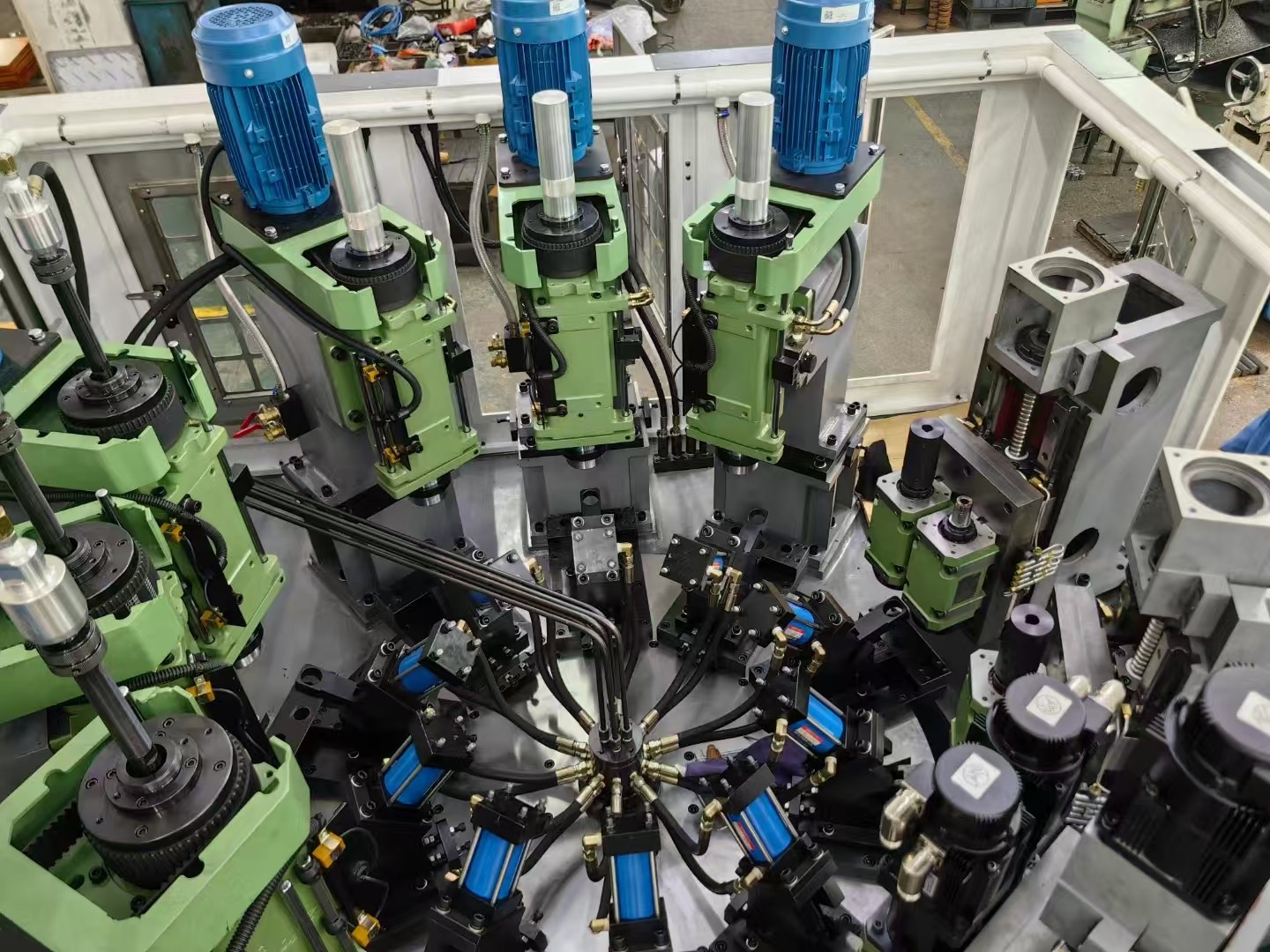

Rotary multi position machining machine, also known as rotary multi station machine tool, is an efficient equipment that uses a rotating turntable to complete workpiece cutting and machining. This type of machine tool can usually achieve automatic tool changing operations for 7-12 workstations, greatly improving production efficiency and reducing labor costs.

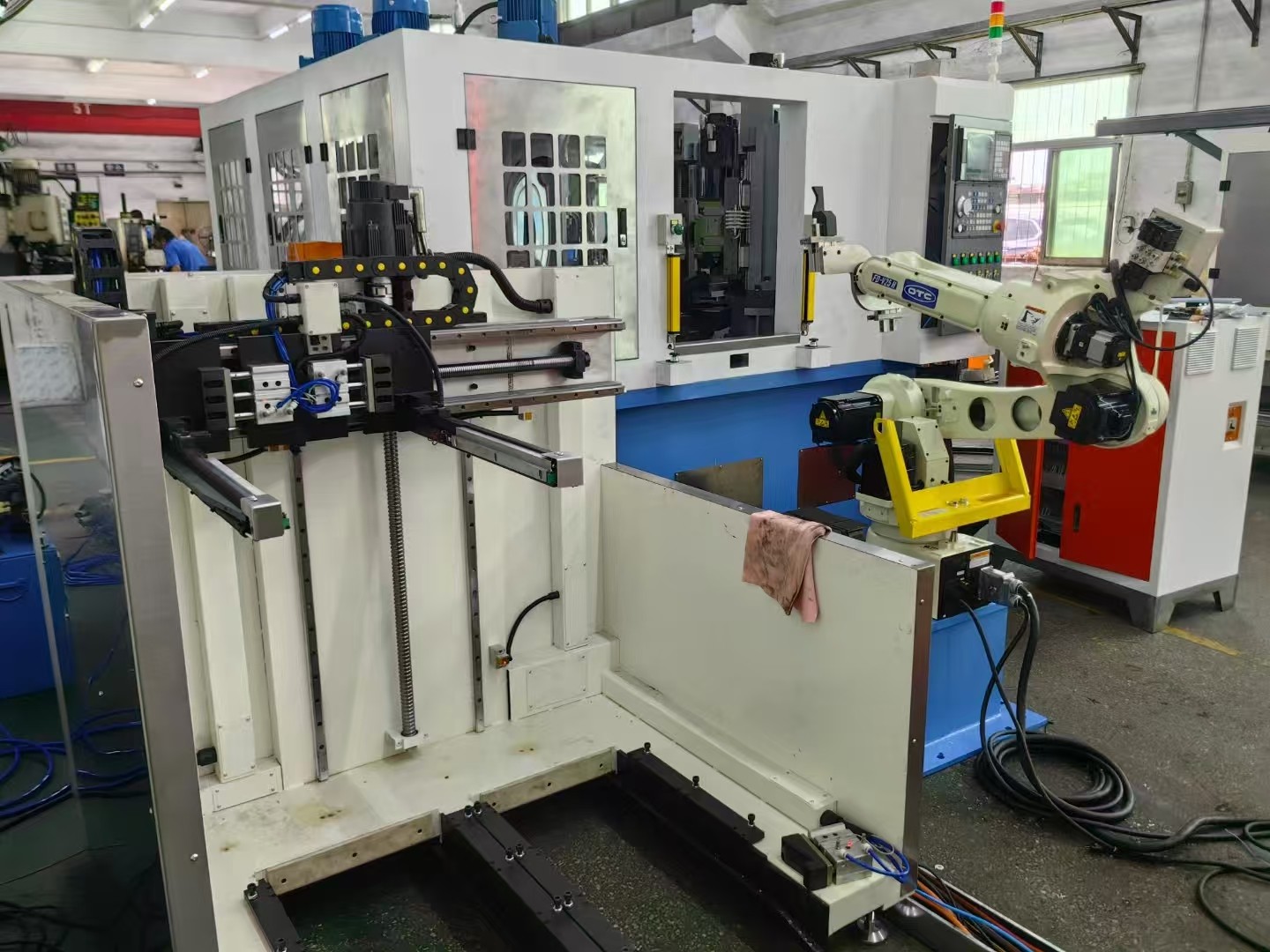

Rotary multi station processing machines have many advantages. Firstly, its multi station design allows each station to work independently, forming multiple processing steps, greatly reducing the ineffective time in the production process and improving production capacity. Secondly, the rotary design allows for unidirectional flow of materials, which is beneficial for the arrangement of site processes. Furthermore, the speed of the turntable can be infinitely adjusted, and the smoothness of starting and stopping is extremely high, ensuring the stability and accuracy of the machining process. In addition, the turntable multi station processing machine also has the characteristics of high precision and high intelligence. By programming the CNC system independently, high-precision and intelligent machining control and parameter settings can be achieved, which is suitable for mass production and complex product processing. Its automatic feeding, positioning, and processing functions make unmanned operation and efficient production possible.

The application fields of rotary multi station processing machines are very wide, including mechanical manufacturing, automotive manufacturing, aerospace, electronics, electrical appliances, instrumentation, toys, hardware products and other industries. It can be used to manufacture various products such as parts, molds, wheels, flanges, etc., playing an important role in improving processing quality, processing efficiency, and process savings.

Overall, the rotary table multi station processing machine provides strong support for the development of modern manufacturing industry with its high efficiency, high precision, and intelligence, and is an important equipment for promoting industrial upgrading and improving production efficiency.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen