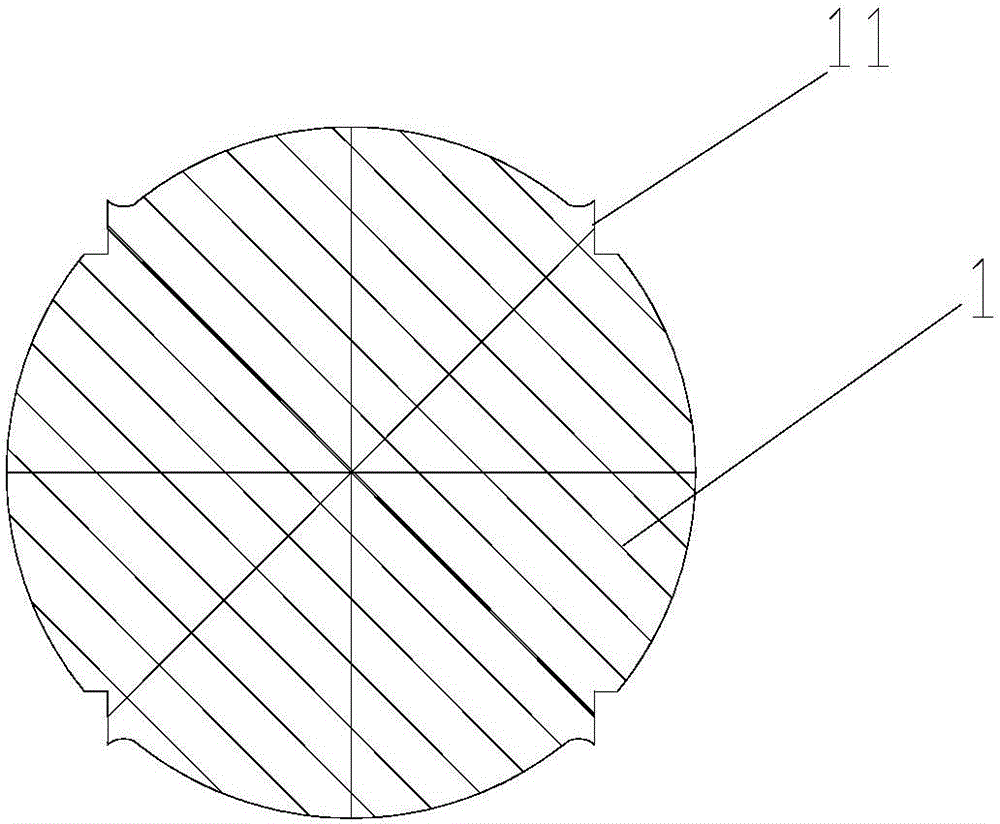

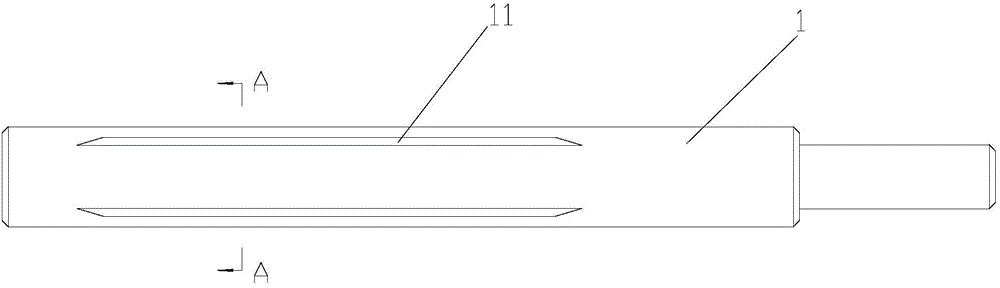

TB2-5-120 Motor shaft knotting automatic pressing machine is an automated equipment used for punching ribs on the outer circumference of motor shafts. It integrates a hydraulic stamping machine and an automatic loading and unloading device, which drives the upper template to move up and down through a slider, thereby achieving the stamping and reinforcement operation of the motor shaft.

A motor shaft knotting automatic pressing machine is a specialized equipment designed to punch ribs (usually 4 or 8 ribs) around the outer diameter of a motor shaft. This process involves machining certain grooves on the motor shaft to make the magnetic field of the motor more uniform and stable, thereby improving the efficiency and performance of the motor.

The main functions of a motor shaft knotting automatic pressing machine include:

|  |

Enhance the strength and load-bearing capacity of the motor shaft: The motor shaft is subjected to various forces during operation. Through punching processing, raised edges and other shaped lines can be formed on the surface of the motor shaft, thereby improving its strength and load-bearing capacity and extending its service life.

Improve the wear resistance of the motor shaft: The motor shaft often comes into contact with metal products or hard objects during operation, resulting in easy surface wear. Punching processing can increase the wear resistance of the motor shaft surface, reduce wear, and thus extend its service life.

The specific steps of motor shaft punching include preparation work (such as cleaning and inspecting the motor, preparing tools and materials), determining the position and size of the shaft punching, and processing the motor shaft punching. After completing the processing, it is necessary to inspect the motor to ensure that the quality and accuracy of the shaft punch meet the requirements.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen