Detailed description of the punching process

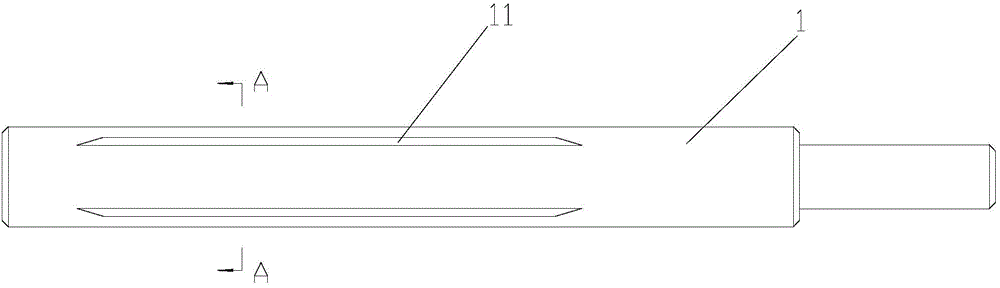

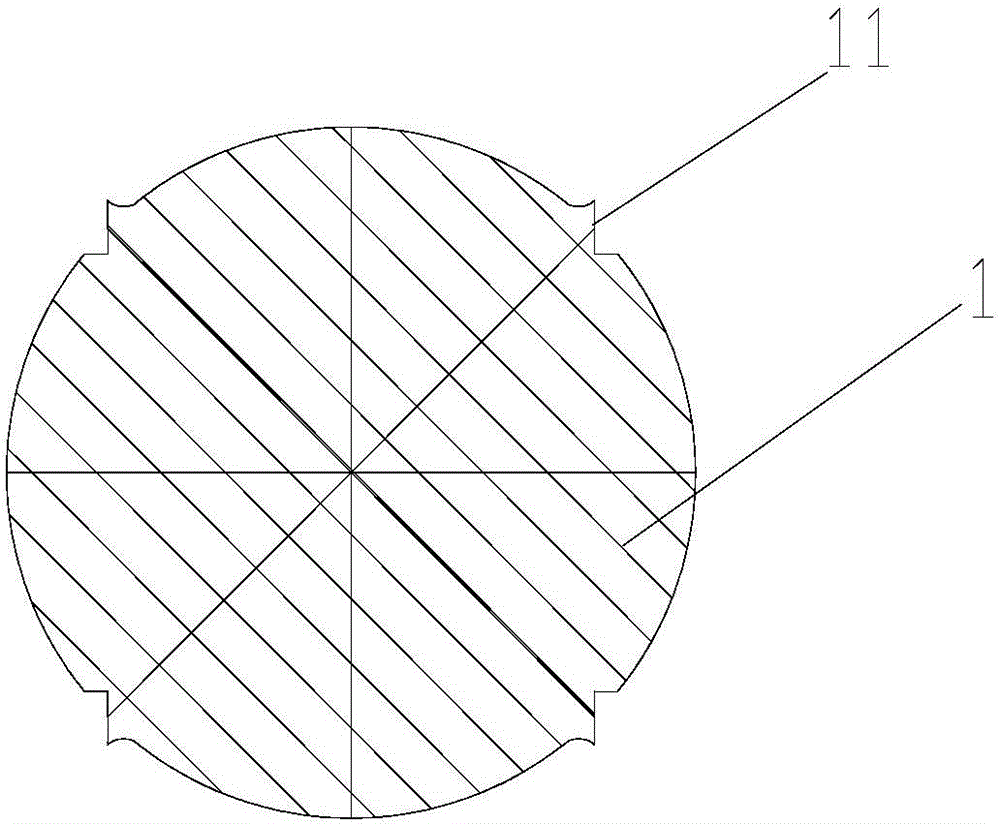

The motor shaft punching process is a machining technique that enhances the strength, wear resistance, and motor performance of the shaft by punching convex ribs on the surface of the motor shaft. The following is a detailed explanation of the punching process, including its function, process flow, equipment characteristics, and search keyword suggestions for foreign markets.

1. The role of the punching process

The main functions of the punching process include:

• Enhance strength and load-bearing capacity:

Punching processing forms raised lines on the surface of the motor shaft, increasing the bending strength and torsional performance of the shaft, thereby extending its service life.

• Improve wear resistance:

Convex ribs can reduce direct wear on the surface of the motor shaft, especially when in contact with bearings or other components, significantly improving wear resistance.

• Optimize motor performance:

Punching can improve the magnetic field distribution of the motor shaft, making the motor run more smoothly and increasing efficiency.

• Easy to assemble:

The surface of the motor shaft after punching is more regular, making it easier to assemble with other components and reducing assembly errors.

2. Process of reinforcement punching technology

The punching process usually includes the following steps:

• Preparation work:

Clean the motor shaft to ensure that the surface is free of impurities and oil stains.

Check the size and surface accuracy of the motor shaft to ensure compliance with the punching requirements.

• Punching processing:

Fix the motor shaft in the mold of the punching machine.

Use hydraulic or mechanical stamping equipment to press the punch into the surface of the motor shaft, forming a convex rib.

According to the design requirements, punch out 4, 8 or more convex ribs.

• Quality inspection:

Check the position, size, and accuracy of the reinforcing bars to ensure compliance with design requirements.

Check whether there are cracks or deformations on the surface of the motor shaft.

• Follow up processing:

Surface treatment, such as polishing or coating, is applied to the motor shaft after reinforcing the ribs to further improve wear resistance and corrosion resistance.

3. Characteristics of motor shaft automatic punching machine

The motor shaft automatic punching machine is an efficient equipment specifically designed for motor shaft punching, with the following characteristics:

• High degree of automation:

Equipped with an automatic loading and unloading device, it can achieve automatic feeding and receiving, reducing manual operation.

High precision machining:

The position of the reinforcing bars is precise, and the spacing between the convex bars is consistent, ensuring the convenience and accuracy of subsequent assembly.

• High efficiency:

Complete the stamping of multiple convex ribs at once, significantly improving production efficiency.

Low noise and vibration:

Adopting advanced hydraulic or mechanical transmission systems, it runs smoothly and has low noise.

• Strong universality:

Suitable for motor shafts of different diameters and lengths, with some devices supporting customization.

• Motor Shaft Rib-Rolling Machine

• Automatic Motor Shaft Rib-Forming Machine

• Motor Shaft Rib-Pressing Equipment

• Shaft Ribbing Machine

• Motor Shaft Reinforcement Machine

• Automated Shaft Ribbing Solution

• Motor Shaft Ribbing Process Equipment

• Shaft Ribbing for Electric Motors

• Electric Motor Shaft Rib-Forming Machine

• Shaft Ribbing Technology for Motors

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen