Motor shaft spline punching machine is an automated equipment designed for processing reinforcing bars (such as straight bars, spiral bars, etc.) on the surface of the motor shaft. Its specifications and processing range vary depending on the manufacturer and application scenario. The following are common specifications and processing range explanations:

1、 Common specification parameters**

1. * * Power parameters**

-Punching force: usually between 5 tons and 30 tons, selected based on material hardness and rib depth.

-Motor power: The main driving motor power is generally 3kW to 15kW.

-* * Speed * *: The adjustable range of spindle speed is usually between 100-1000 revolutions per minute.

2. * * Structural parameters**

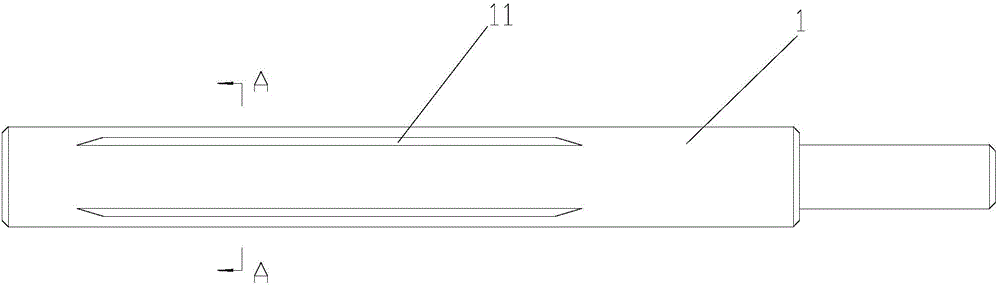

-* * Processing axis length range * *: Supports axis lengths from 50mm to 500mm (equipment needs to be distinguished).

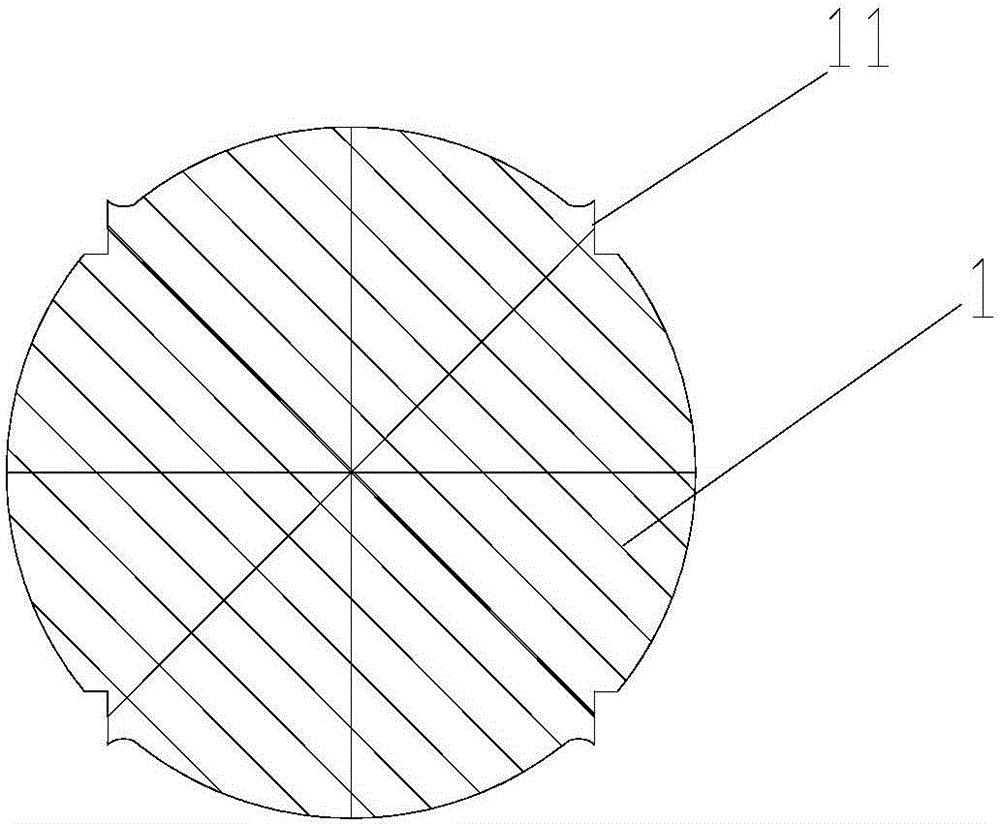

-* * Shaft diameter range * *: It can usually process shaft parts with a diameter of 10mm to 30mm.

-Mold adaptability: Supports multi station molds and can simultaneously process multiple ribs or ribs of different shapes.

3. * * Control System**

-Automation level: PLC or CNC control, supporting programming to set parameters such as rib position, depth, angle, etc.

-* * Operating interface * *: Touch screen human-machine interface, which can preset multiple processing modes.

-Accuracy: The positioning accuracy can reach ± 0.05mm, and the repeatability accuracy is ± 0.02mm.

4. * * Additional Features**

-* * Automatic feeding/unloading * *: Equipped with a robotic arm or conveyor belt to achieve fully automated production.

-Cooling System: Optional cutting fluid or air cooling device to prevent material overheating.

###2. Processing Scope**

1. * * Axis dimensions**

-* * Length * *: 50mm to 500mm (can be longer for special customized models).

-* * Diameter * *: 10mm to 30mm (some heavy equipment can process larger diameters).

2. * * Reinforcement parameters**

-* * Bar shape * *: Straight bars, etc.

-Number of reinforcement bars: 4, 8 or more symmetrically distributed.

-* * Reinforcement size * *:

-Height: 0.5mm to 1mm (adjusted according to the punching force).

-Width: 0.3mm to 0.5mm (requires matching mold).

3. * * Applicable materials**

-Metal materials such as carbon steel, alloy steel, stainless steel, etc.

-The device does not support hard alloy or surface treated shaft machining.

4. * * Processing efficiency**

-Single axis processing time: about 2 seconds (28 pieces for 4 bars, 22 pieces for 8 bars/minute).

-Capacity: 1200 to 1600 pieces per hour (in continuous production mode).

---

###III. Typical Application Scenarios**

1. * * Motor industry * *: Used for processing motor shafts, stator shafts, servo motor shafts, etc.

2. * * Automotive industry * *: Processing of ribs for components such as transmission shafts, drive shafts, differential shafts, etc.

3. * * Mechanical manufacturing * *: Scenarios that require enhanced structural strength, such as pump shafts, gear shafts, and tool machine spindles.

---

###4. Selection Suggestions**

1. Select the equipment model based on the shaft size (diameter, length).

2. Match the punching force according to the requirements of material hardness and rib depth.

3. For high-precision requirements (such as servo motor shafts), CNC control models are preferred.

4. Large scale production requires an automatic loading and unloading system to improve efficiency.

If further customization is required (such as special rib shapes or ultra large shaft processing), technical details need to be communicated with the manufacturer.

Contact: Sam

Phone: +86 186 8899 7860

E-mail: info@boosum.com

Add: No. 109, Houting Second Industrial Zone, Shajing Street, Bao'an District, Shenzhen